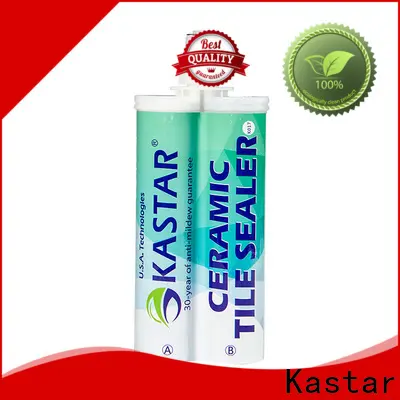

Kastar epoxy resin grout manufacturing top brand4

Start Port:

Guangzhou

Payment:

TT,LC ,Paypal,Western Union

MOQ::

5000 pcs

Delivery time:

30 days

Certification:

SGS,CE

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Products

Contact Us

Whatsapp:+86 18867419465

Wechat:+ 86 18867419465

E-mail:kateradhesive@kater-adhesive.cn

E-mail:kateradhesive@kater-adhesive.cn

Address:

No.1, ShunJing Road, Songxia Industrial Park, SongGang Town, Foshan, China