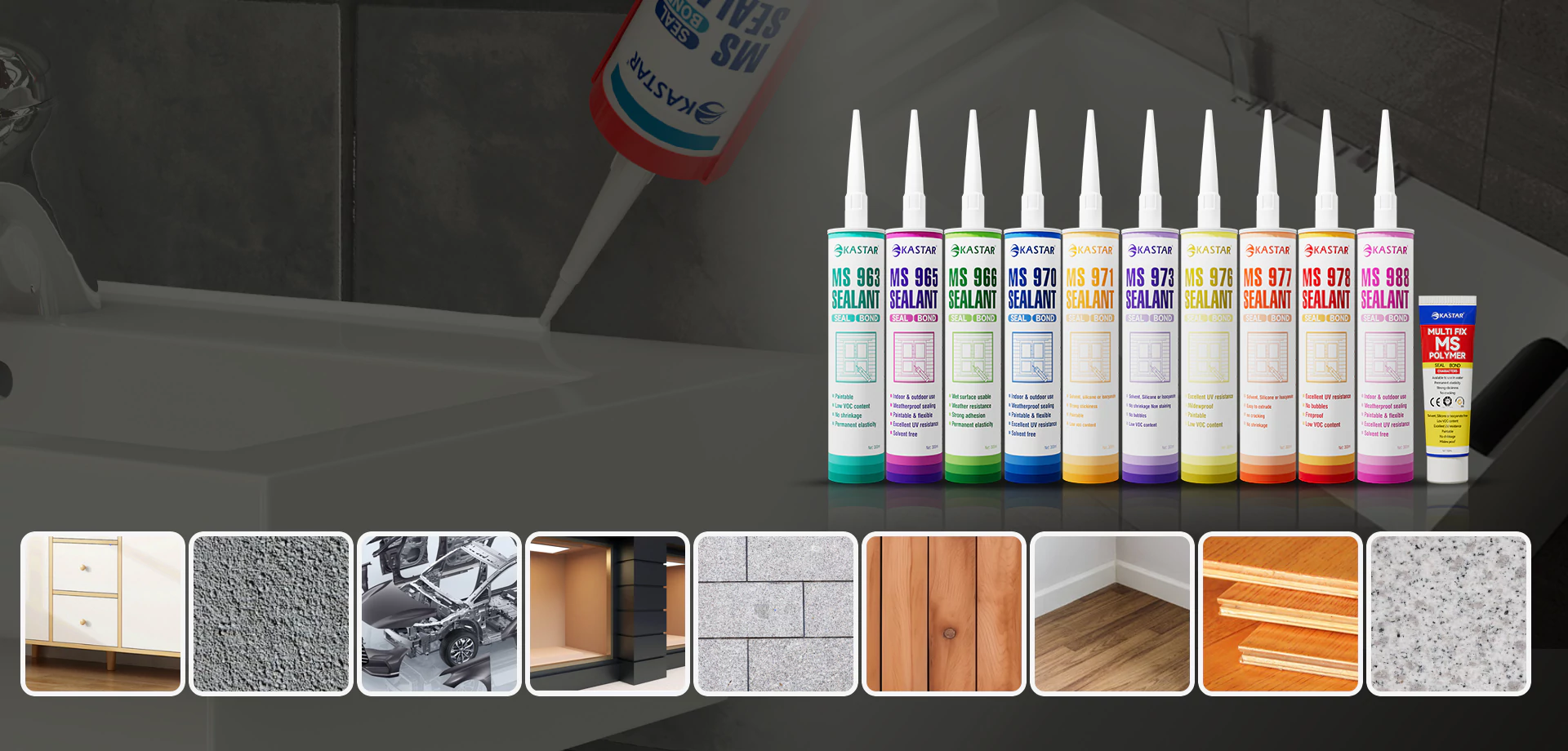

Hybrid MS polymer sealant

The Hybrid MS polymer sealant is a cutting-edge adhesive that combines the best features of silicone and polyurethane sealants. This advanced formula offers superior adhesion, flexibility, and durability, making it suitable for a wide range of sealing and bonding applications. Whether used in construction, automotive, or general bonding purposes, the Hybrid polymer sealant provides excellent weather resistance and is paintable, ensuring seamless integration into various projects. With its versatility and high-performance characteristics, this sealant is a reliable choice for professionals and DIY enthusiasts seeking a durable and multi-functional sealing solution.

Kastar MS sealant is also known “ Modified Silicone” which overcomes a number of performance issues associated with Silicone and PU sealants. Available for sealing of Aluminum Composite Panel (ACP), Concrete joint, Window Perimeter, Natural stone, Granite, Ceramics, Marble, Porcelain, Metals, PVC,Glass, Wood, Concrete, Brick, Limestone and so on.

It meets the Low VOC, Eco-friendly, Weatherproof better than PU sealant, and has excellent bonding underwater or wet surface.

KASTAR MS sealant offers cost-savings and efficiencies for uses in a variety of applications including fenestration, off-site construction and artificial grass.

MS polymer sealant works by a moisture-triggered "silane-crosslinking" reaction that turns a soft paste into a flexible, durable rubber.

1. Moisture attack

Air humidity diffuses into the sealant and hydrolyses the terminal –Si(OCH₃)₃ groups → methanol vapour escapes and highly reactive –Si(OH)₃ "silanols" appear.

2. Self-crosslinking

Two silanols condense, eliminating water and forming –Si–O–Si– bridges. Repeat thousands of times → a continuous 3-D siloxane network is built inside the polyether (or PU) chain matrix.

3. Adhesion in the same step

The same silanols also react with –OH groups on glass, concrete, metal, PVC, wood, etc., covalently grafting the sealant to the surface—no primer needed on most materials.

4. End result

Within minutes a skin forms; within hours-to-days the bead is a low-modulus, high-elongation (>300 %) elastomer that stays flexible from –40 °C to +100 °C, resists UV, water and chemicals—no bubbles, no shrinkage, no isocyanate risks.

Kastar MS sealant is a new generation single component joint sealant and high strength adhesive. It is based on MSPolymer, chemically neutral and fully elastic. Tradeseal MS60NG is formulated for use in low movement joints in construction, automotive and marine and areas where a tough, flexible and waterproof rubber seal is required.

Kastar MS Polymer Sealant is suitable for bonding and sealing in industrial and refrigerated trailers, commercial vehicles, cars, vans, caravans and motorhomes. Prior testing for paint is highly recommended, and if the application is always to be overpainted, the use of PU40FC Easygun is advised instead.

Kastar MS Polymer Sealant is suitable for bonding and sealing in sandwich panel manufacture, signmaking and fixing, composite panels, ducting, metal constructions which are subject to vibration, etc.

Kastar MS Polymer Sealant is suitable for bonding and sealing in the building industry, internal and external, to bond and seal elements which may be subject to vibrations or deformations. The adhesion is excellent on a wide range of substrates including tiles, plaster/plasterboard, glass, timber and timber based products, PVC hygienic cladding, most metals, polystyrene, stone, concrete, etc.

Key Features and Performance of MS Polymer Sealant:

MS sealants are growing in popularity primarily due to their versatility and balanced performance. Some even surpass other high-performance sealants.

MS Polymer Sealant Information

| Chemical Base | Silane Modified Polymer |

| Curing Mechanism | Moisture Curing |

| Color | White/Black/Grey |

| Density | 1.58+0.1 gr/ml |

| Tack Free Time | 10-15 min (23'℃ and %50 R.H.) |

| Cured depth (24hours) | >3mm (23°Cand %50 R.H.) |

| Tensile Strength | ≥2.9MPa |

| Elongation at break | ≥250% |

| Shear stress | 2.9MPa |

| 100% Tensile Modulus | ≥1.65MPa |

| Application Temperature | +5'C to +35°C |

| Temperature resistance | -50'C to +120°C |

We produce hybrid sealants based on MS Polymer technology with weathering characteristics that are superior and will not crack within a short period of time.

Get in Touch with Us

We provide One-Stop Solution Service of high-performance MS Polymer Sealants, contact us today to learn more about MS Sealant today!